Energy Storage Knowledge | BESS Local Control and Remote Communication

这里是标题一h1占位文字

Apr 10,2024

The BESS online real-time control device is divided into two levels: the bottom level islocal control devices, which mainly complete the coordination and control of bottom-level components such as energy storage inverters, energy storage units, and environmental and safety assurance devices; the top level isEMS, which mainly optimizes the operation mode and power-time curve based on external information such as the economic model of energy storage application scenarios, historical and forecast data, real-time data from bottom-level devices, and electricity pricing policies. It is a control system completely independent of BESS.

1.1 BESS Local Control and Management Architecture

The internal communication architecture of BESS integrates high and low voltage switchgear, transformers, PCS, battery junction boxes, BMS, and other auxiliary systems or sensors. The internal communication links between various devices are built based on local controllers to achieve real-time information sharing and coordinated scheduling, which is currently the main way to manage multiple internal devices.

BESS Local Control and Management Architecture Diagram

1.2 Local Controller Hardware Platform

According to the management scope, it is calledenergy storage system controller, according to its control cycle or time, it is calledreal-time controller (RTC), according to its installation location, it is calledcontainer controller (CC). The main functions include: realizing information collection and recording of the internal environment and bottom-level devices of BESS, uploading internal data to the SCADA system and EMS control system, receiving scheduling instructions, and coordinating the work of internal devices based on the system's real-time status and external instructions to achieve control objectives; taking autonomous measures to implement fault protection, fault recording, and diagnosis functions in emergency situations.

1.3 Battery Energy Storage System Operating Status and Control Logic

Taking the grid-connected BESS as an example, local control mainly completes functions such as system self-check, device startup, PCS power scheduling, alarm operation, and fault protection. The entire working process is divided into seven main states: full blackout, power on, standby, startup, operation, fault and alarm, and shutdown.

BESS State Transition Diagram

The BESS connects to the power station data collection and monitoring (SCADA) system to achieve external data communication mainly throughserial communicationandEthernet communication. Serial communication mainly uses the RS485 interface standard, suitable for building small-scale monitoring systems with low real-time requirements; Ethernet communication has advantages such as high speed, good scalability, and high reliability, making it suitable for large energy storage power stations or application projects.

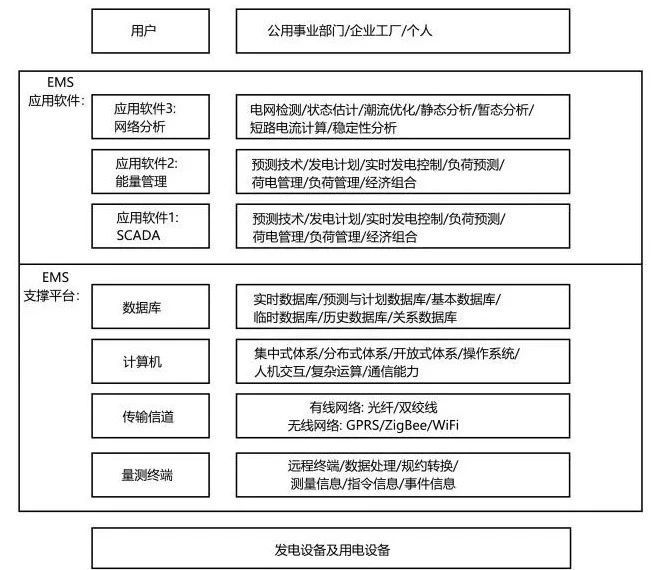

EMS Energy Management System:The SCADA system collects and centrally displays real-time information and data related to power system equipment, allowing dispatchers or operation and maintenance personnel to timely and intuitively grasp the system's operating status and make manual intervention instructions or correct operating parameters. With the development of new energy, especially distributed energy and energy storage technology, EMS can be broadly extended to comprehensive management and scheduling of energy, distribution, and load within a region, achieving internal optimization and friendly access to external power systems while providing support services within its capabilities.

EMS Overall Architecture:It mainly consists of a supporting platform and application software. The supporting platform mainly includes measurement terminals, transmission channels, computers, databases, etc.; the application software corresponds to the three main functions of EMS, namely data collection and monitoring, energy management, and network analysis.

EMS Overall Architecture

Keyword:

News Information

Innovation and Quality Driven | 2024 Light Storage Innovation List Wins 3 Major Awards